APPARATUS REQUIRED

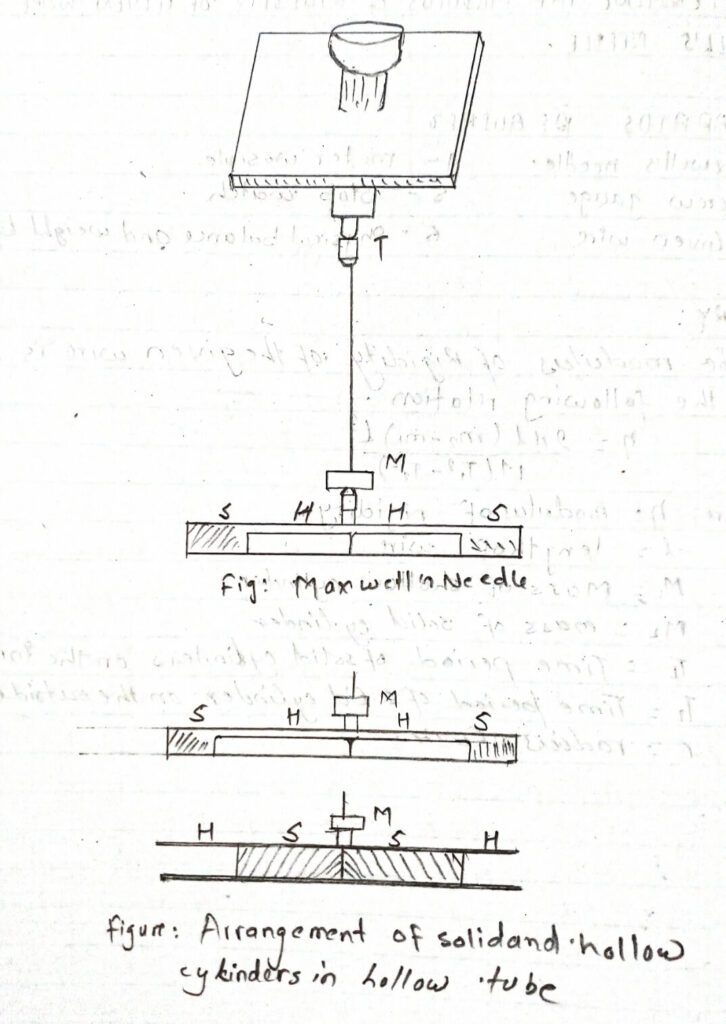

i) Maxwell’s needle.

ii) Screw gauge

iii) Meter scale

iv) Stopwatch

v) Given wire

vi) Physical balance and weight box.

THEORY:

The modulus of Rigidity of the given wire is calculated by the following relation.

η = 2πl(m2-m1) l3 / r4(T21-T22)

Where, η = modulus of rigidity.

l= length of wire

M1 = Mass of hollow cylinder

M2 = mass of solid cylinder

T1 = Time period of solid cylinders on the innerside

T2 = Time period of solid cylinder on the outside

r= radius of wire

OBSERVATION:

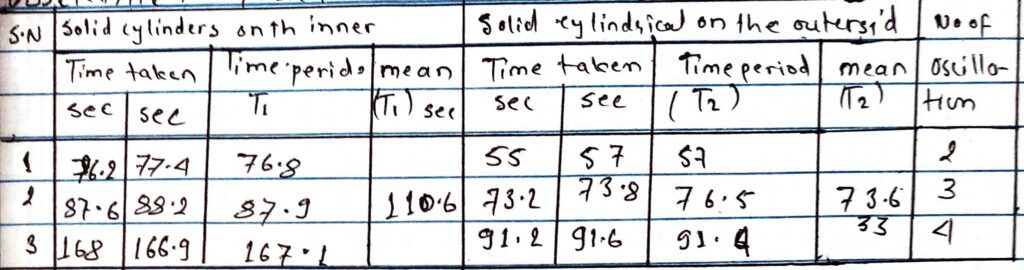

Table for determination of T1 and T2

length of wire (l) =79cm =0.79m

length of maxwell’s needle (l) = (0.41) m

Mass of hollow cylinder (M1) = 50 gm = 0.05kg

Mass of solid cylinder (M2) = 250gm = 0.25kg

Radius of wire (r) = 45×10-5/2 m

CALCULATION

Modulus of rigidity (η) : 2π(m2-m1)l2 / r4(T21-T22)

= 2π(0.25 -0.05) (0.41)2 / (45X10-5/2)4 [(110.6)2-(73.633)2]

= 9.40×109 N/m²

PERCENTAGE ERROR

Standard value 7η = 1.7 × 1011 N/m2

observative value (η) = 9.4×109 N/m²

Here error = Standard value-observative value / Standard value X100%

= 94.5%

RESULT:

Thus the modulus of rigidity of the given wire was found to be 1.40X 109 N/m2

CONCLUSION

Thus the modulus of rigidity of the given wire can be determined by using Maxwell’s needle.