APPARTUS REQUIRED

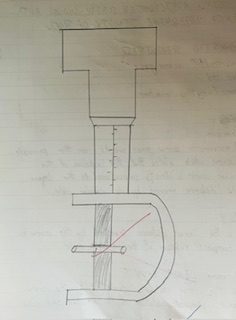

1 A micrometer screw gauge

2) Glass rod

3) Balance / weighing machine

THEROY

Principle 1

A micrometer screw gauge works on the principle of screw which states that the rotation of the circular scale is directly proportional to the linear scale / distance moved by its circular scale.

PITCH

It is the linear distance travelled by screw one complete rotation of the circular scale

LEAST COUNT

It is the linear data travelled by the screw in one complete rotation of the circular one scale.

L.C = Pitch/ Total no of circular division

P/N

If d is diameter, l is the length of the glass rod and m is the mass of the glass rod then, the cross sectional

area of glass rod is

A = πd²/4

And its density is given by.

P= m/A X L

OBSERVATION

1) For the least count

value of 10 main scale division = 10mm

Value of 1 main scale division = 1 mm

No. of circular scale division = 100

In 5 complete rotation, screw advances through 5mm main scale division.

In 1 complete rotation, screw advances through 1msd

Pitch: Linear distance traveled by the screw in 1 complete rotation.

P = 1 m.s.d. = 1mm.

L.C.= P/N = 0.01mm

2) For zero error

Zero correction=

Length of the rod = 1.55

Mass of the rod(m) = 1.02gm

Table of measurement of diameter

| No. of obs. | M.S.R.(Xmm) | C.S.R.(Ymm) | Value of C.S.R[YxLC] | Total X+[XxLC] | Mean diameter | Corrector I error |

| 1. | 5 | 0 | 0 | 5 | ||

| 2. | 5 | 90 | 0.9 | 5.90 | ||

| 3. | 5 | 85 | 0.85 | 5.85 | ||

| 4. | 5 | 86 | 0.86 | 5.86 | 5.33 | |

| 5. | 5 | 86 | 0.86 | 5.86 | 5.783 | |

| 6. | 5 | 87 | 0.87 | 5.87 | ||

| 7. | 5 | 88 | 0.88 | 5.88 | ||

| 8. | 5 | 88 | 0.88 | 5.88 | ||

| 9. | 5 | 86 | 0.86 | 5.86 | ||

| 10. | 5 | 87 | 0.87 | 5.87 |

Calculations

length of the rod.(1) = 1.55

Mean diameter (d ) = 5.783m = 0.5783cm

Cross sectional area

A = πd2 / 4

= 22 (5.75) ² / 4

= 0.2600 47 cm

Mass of rod = 0.63g

Density p = m / AxL

= 0.69 / 0.260047 × 1.55

= 1.711849359 g/cm3

Percentage error

Standard value of density of glass, pg = 2.5 g/cm3

Observed value of density of glass, po= 1.711849

Percentage error = |Pg – Po / Pg | x 100%

= |2.5-1.504 / 2.5|x 100%

= 3 %

Percentage error = |Pg – Po / Pg| x 100%

= | 2.5 – 1.711849 / 2.5 | x 100%

= 39.84 %

RESULTS

The density of material of given gas was found to be 1.504% 1.711849 g/cm ³ from the experiment.

CONCLUSION

Diameter of the given glass rod is measured by using a micrometer screw gauge and the density is determined.

PRECAUTIONS

1. The glass rod should be placed between two studs. properly.

2. The zero error should be determined carefully.

3. The screw should always be turned in the same direction to avoid backlash error.